Many years back, I was working as a Planner for a large Machine Tools Building Organization. These machine tools were custom built long lead time high value CNC machines. Delivery to customer on time is critical as the customer's production commitments to their customers is linked to our delivery on time.

Moment we get the customer order for the machine, we will start planning the delivery very meticulously. Purchase orders for long lead time imported items like controls and systems will be released in advance close follow up with suppiers will be done periodically. Everything will look good till the delivery due date comes close by ......

What will blow up on our face is the few hundred dollars sheet metal cover panels we would have ordered from a local vendor who is just 10 miles away. Either the delivery will be missed or the quality is not up to standards. That will call for rework and missed delivery. Lesson learnt, the definition of critical item can be misleading. A seemingly low value low important item can prove to be the critical items.

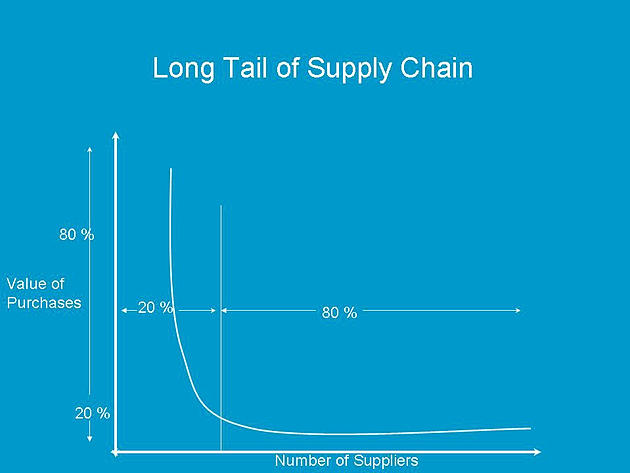

We are all lead to believe that Peroto 80/20 principle applies to all sectors of business. Manage 20% of the vendors who supply 80% value of the material. We tend to neglect the long tail of the supply chain. The small vendors who supply 80% of the bulk of the material. A good supply chain should mange these vendors also very carefully.

Due to the number of suppliers who fall in this long tail, it is difficult to manage them individually. We need to have a system in place to manage and monitor these supplies. Some of the helpful practices are

1. Ensure that these suppliers acknowledge and confirm the receipt of your purchase orders. This will ensure that they are committed to the delivery. While email confirmation is good, if you can get them on boarded on to your vendor portal that will be better.

2. Pre delivery notifications - This is also called advance shipment notification (ASN). This will ensure that the suppliers are shipping the material in time and they provide needed documentation like quality inspection reports, product images etc.

3. Quality Feedback - It is necessary to provide periodical quality feedback to these suppliers and keep them engaged. Any quality feedback provided to these suppliers should be acknowledged by the suppliers and their action plan to improve on the quality should be recorded.

4. Performance metrics - There are many metrics on which the supplier should be able to constantly evaluation themselves. For example , on time delivery percentage, percentage of rejection, price trend over volume etc.

This kind of a closed loop system with not only your primary vendors but also the long tail vendors is essential to keep your supply chain engine running smoothly. To manage efficiently the suppliers in long tail of your supply chain, you can use one of the best supplier portal available in the market.

No comments:

Post a Comment