|

| QuickBooks Integration |

QuickBooks and External Systems

QuickBooks is the most widely used Accounting Software in Small and Medium Businesses. What was a simple accounting book keeping system has progressed to a full ERP and Supply Chain Management System. Check this article on how QuickBooks is being used in Supply Chain Systems. QuickBooks as Supply Chain Management Solution

Integrating QuickBooks to External Systems

Many a times it is necessary to get the data into and out of QuickBooks in a bulk. For example if you are a supplier selling to Amazon, Amazon will send EDI (Refer this article on EDI ) messages for Orders. It is necessary to post them into QuickBooks automatically. If there are only few orders to be managed, it can be entered into QuickBooks manually. But if there are hundreds of orders to be processed, it is not possible to do it manually. You will need an automated solution to manage the Orders.

Similarly, data between QuickBooks and External CRM system or sales portal needs to be synchronized.

Integration Methods

Integrating to QuickBooks depends upon if it is Online Version or Desktop Enterprise version

Integrating to QuickBooks Online Version

QuickBooks Online API is the easy method to connect to QuickBooks Online version. External applications either cloud based on on premise can use the API to access QuickBooks Online and extract data and post data.

Integrating to QuickBooks Desktop Version

|

| QuickBooks Web Connector |

The challenge with desktop version is accessing the company by external systems outside the company network. While the online version is hosted by Intuit in the web, desktop version is maintained by the user within their company network.

QuickBooks provides a solution called 'Web connector' for this. Web connector is a small windows based application that runs inside the company network. Either on the same machine where QuickBooks is installed or in another machine within the company.

This web connector can call any external applications and transfer data in between.

The Web connector provides an intermediate connection between the external system and quick books desktop.

As the web connector only calls the external system and external system can not start the call, this connection is secure and safe to use.

What the Integration can do

It is possible to exchange a variety of data between QuickBooks and External systems.

For example,

- Purchase orders from customers like Amazon, Walmart will be posted as Sales orders into QuickBooks.

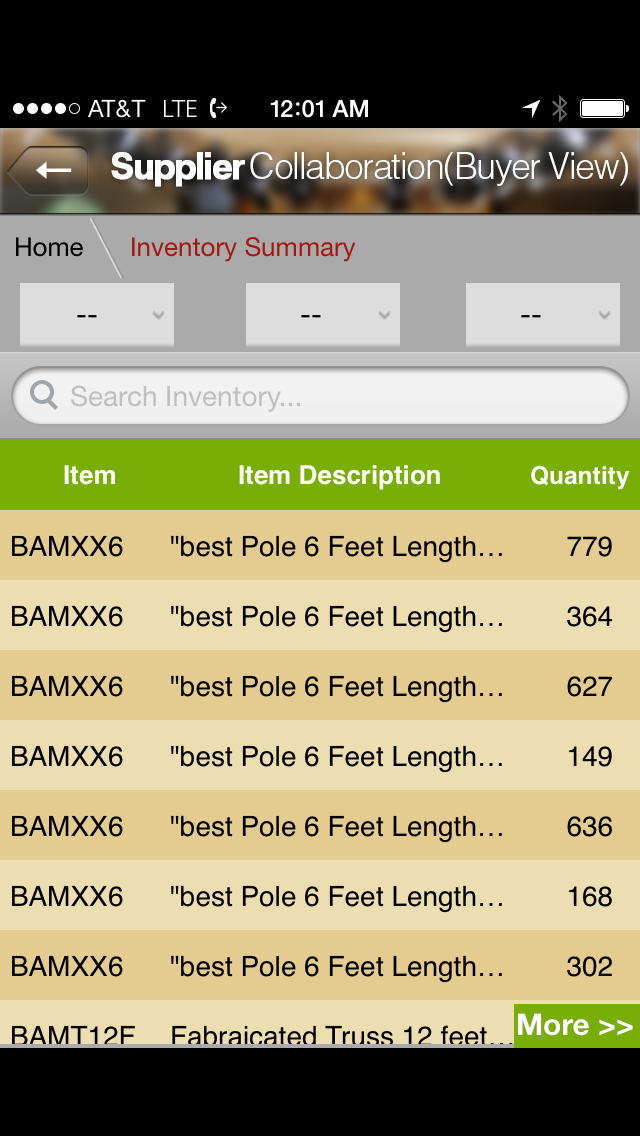

- Products and Inventory maintained in QuickBooks will be synchronized to online web stores like Shopify, Amazon or other market places.

- Sales made in external websites will be posted as customer receipts into QuickBooks

- New customers acquired through other CRM tools will be created as customers in QuickBooks.

- Invoices created in QuickBooks will be electronically sent to customers like Amazon,Walmart through EDI.

How QuickBooks users should develop these Integrations

It is not necessary to reinvent the wheel. There are many Intuit certified apps out there that can do all the integrations mentioned above. For example if you need to accept EDI messages from your customers and send EDI invoices, TPSynergy as listed in the Intuit QuickBooks EDI App is a good choice for ready made EDI integration.